Aerodyne’s DT3 solutions are resolving complex pain points of major industries worldwide by offering valuable capabilities for applications for renewable energy infrastructures such as wind turbines (WTG) and solar farms.

Wind Turbines (WTG)

- Structural inspections of WTG, onshore & offshore.

- End-of-warranty audit.

- AI driven defect detection.

- Prescriptive analysis.

End-to-end Solutions for WTG Asset Inspection and Management

Automated WTG Inspection

High Quality and close up shots of wind turbine condition for better identification of defect.

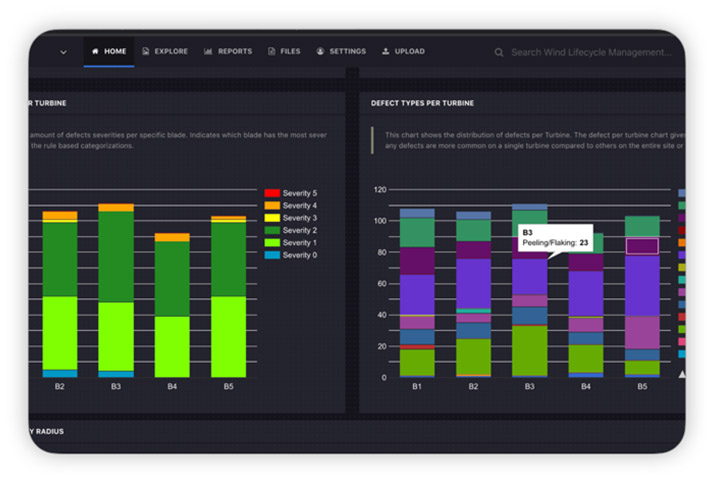

Reporting and Analytics

Quick automated report generation which specifies and categorize the defects marked according to its severity level.

Robotic Blade Care Services

High Quality and close up shots of wind turbine condition for better identification of defects.

Automated WTG Inspection

Improve Operation Productivity

- Inspect average 8 WTGs per day with automated flying waypoints and distance lock. Aerodyne solutions perform smooth inspections for long and repetitive features on WTG blades.

- With the distance lock, the resolution of the data can be captured at 1mm per pixel to ensure data quality for defect marking.

Proven Methodology

Improve Efficiency and Effectiveness

Eliminate Safety Risk of Blade Inspections

High Resolution Data

Reporting and Analytics

Detailed Insights of the Blades

- Using the high resolution data, our blade experts are able to perform inspection on our proprietary desktop application.

- Eliminates costly inspection using rope access, lifts or cranes for inspection.

- Condition-based monitoring, a proactive approach to blade maintenance reduces the cost of repairs by providing insights into critical damages.

Experienced In-house Blade Specialist

Improve Effeciency in Reporting

Collaborative Platform

Turning Drone Data into Actionable Data

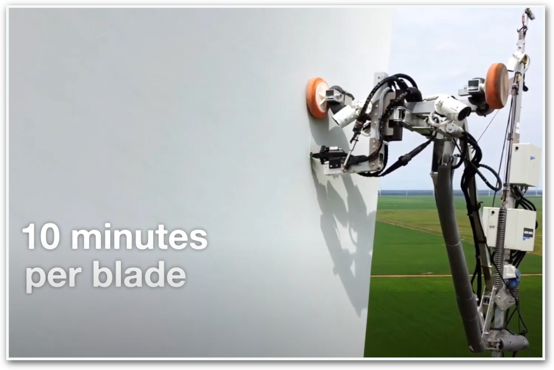

Robotic Blade Care Services

Lightning Protection System

Conduct full circuit tests for conductivity testing. Determine the working condition of LPS system without sending people to work at height.

Blade Cleaning/Painting

Efficient removal of dirt. Approximately 10 hours of blade cleaning and painting per turbine. Faster and safer way to repaint inspected turbine.

Internal Inspection

High quality internal inspection using 360 camera. Able to view the full damage extent visible from inside of the turbine.

- Safer

- Cost Effective

- Faster

- Better

- Faster

- Better

- Safer

- Cost Effective